Austempering is a form of heat treating that when applied to certain metals allows for greater tensile strength, more consistent hardness, and lower distortion when compared with conventional treatments.

Conventional heat treating calls for parts to be heated in a controlled atmosphere, quenched in a bath of oil or water at around room temperature, and then tempered again to reduce brittleness.

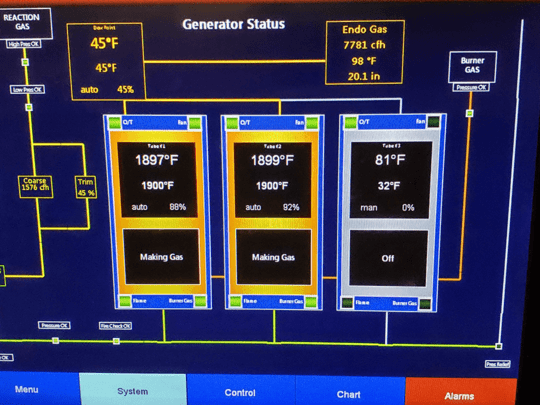

Austempering calls for parts to be heated and then quenched in a molten salt bath (rather than oil or water) at a much higher temperature, usually 450°F (232°C) to 750°F (399°C). The resulting structure, bainite for austempered steel (ausferrite for iron) is quite different from the martensite created by traditional methods.

This new structure (bainite) exhibits a 15% higher tensile strength, 24% higher yield strength, and at least a tenfold increase in reduction of area and impact when compared to an identical specimen conventionally quenched and tempered to an equivalent hardness.

Production atmosphere to salt lines did not exist and the salt-to-salt lines available were generally small, manually operated units suited only for short runs. Although the properties of austempered parts were known to be superior to quenched and tempered parts, the process was not cost effective. Therefore, it was mostly used in specialty applications.

In the mid 1950's United Car Fasteners in Ames, Mass. Converted an air atmosphere, oil quench belt furnace to a nitrate/nitrite salt quench. This furnace was modified to process medium carbon, thin stamped springs and fasteners. It's capacity was about 400lb/hr, but lack of atmosphere and the absence of quench agitation limited its productivity. The fear of explosion by maintaining a carbon bearing atmosphere over a nitrate salt bath discouraged equipment manufactures from pursuing this technology.

Until this time, the cost of austempering had averaged roughly 10 times that of the cost of conventional hardening. This new technique dropped the cost to roughly twice that of quench and tempering. Even though the cost of this was still high, the popularity of austempering increased rapidly with manufacturers of formed steel clips because of the uniform hardness, toughness and lower distortion exhibited by parts processed with this new high capacity system.

By the late 1960's austempering had become a commercially accepted alternative to traditional quenching and tempering. The automotive companies, agricultural equipment manufacturers, and the U.S. military had all included the austempering process in their specifications. Refined atmosphere control, quenching enhancement techniques, and new loading mechanisms further improved the process. Engineers began specifying austempering on their blueprints and larger corporations and commercial heat treats began installing high volume, automated and semi-automated lines of both salt-to-salt and atmosphere to salt equipment in their plants.

In the 1970's salt-to-salt equipment manufacturers began offering fully automated lines with capacities of up to 1000 lb/hr. In 1978 AFC introduced a mesh belt austemper furnace. This furnace had all of the advantages of the cast-link belt systems but eliminated the separate loading conveyer. This allowed the parts to pass through the furnace from loading to quench in the same orientation making hand loading of difficult parts possible. These mesh belt units were capable of 1500 lb/hr. In the 1990's as well as in the next century, engineering requirements will become more stringent, and the benefits of low distortion, consistent hardness, and better wear resistance will become necessities for competing in a world market. Often, subsequent inspection, coiling and machining operations can be minimized or eliminated by converting to an austempering process. From a process control perspective this makes austempering a very attractive alternative.